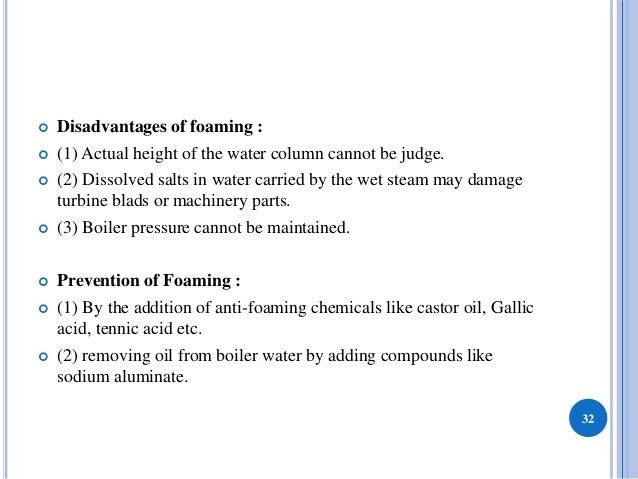

Disadvantages Of Foaming In Boiler

Bubbles or froth actually build up on the surface of the boiler water and pass out with the steam.

Disadvantages of foaming in boiler. An increase in temperature results in an increase in electrical conductivity. If it goes too high alkaline the water will foam and prime. The furnace which provides heat usually by burning a fuel and the boiler proper a device in which the heat. Since this variety of boiler draws its water directly from the mains no hot or cold water cylinder or storage tank is required.

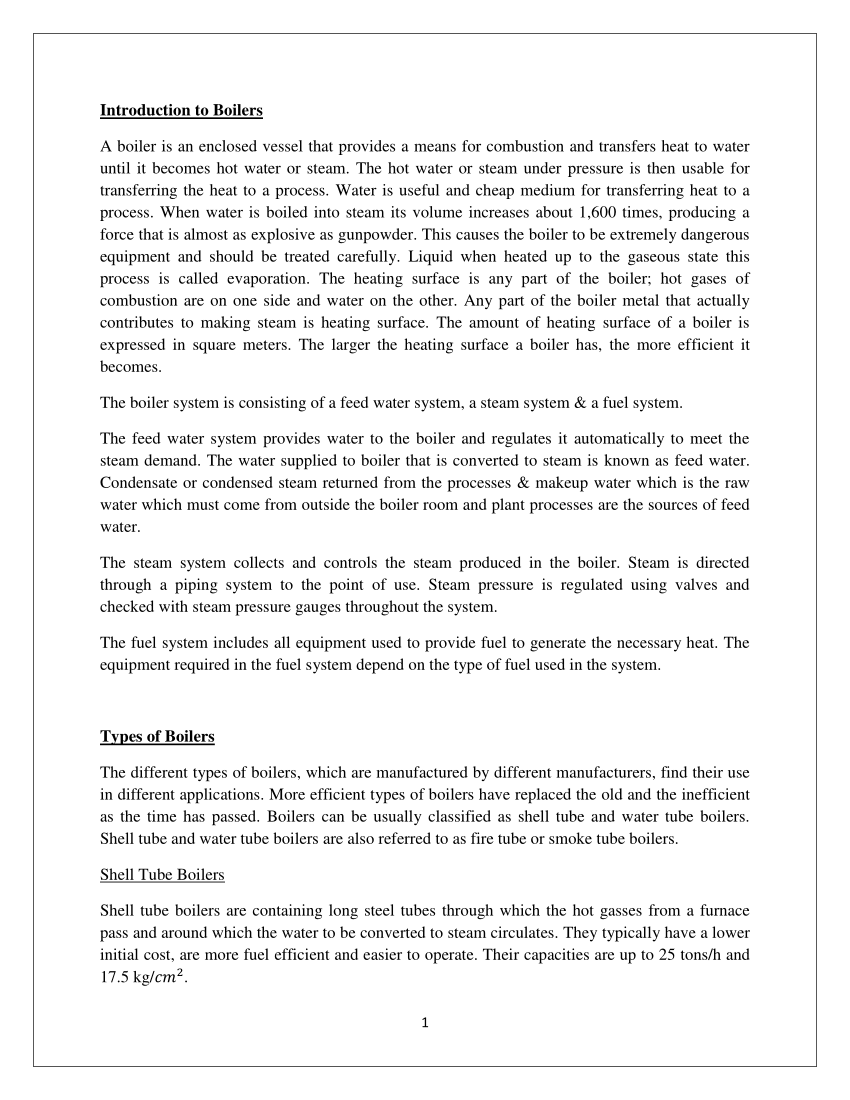

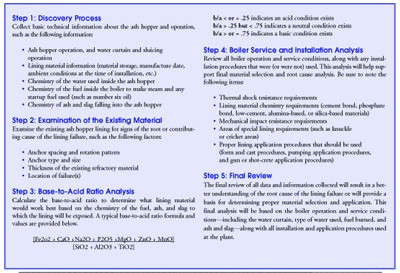

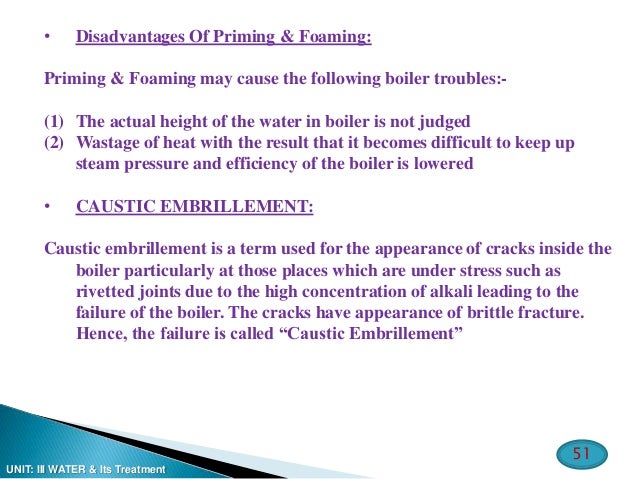

Surface definition foam on a glass of beer sits on top of the liquid and the liquid foam interface is clearly defined. Carryover also known as priming is any solid liquid or vaporous contaminant that leaves a boiler with the steam. For boiler water the conductivity increases at the rate of approximately 2 of the value at 25 c for every 1 c increase in temperature. Index boiler and boiler feed water boiler problems sludge and scale formation priming foaming carry over boiler corrosion caustic embrittlement 2.

A boiler water sample has an unneutralised conductivity of 5 000 μs cm at 25 c. In low medium pressure boilers 100 bar entrained boiler water is the most common cause of steam contamination. A combination boiler owes its name to the fact this variety of boiler functions as a duel hot water and central heating devise. This is called foaming and it is caused by high concentration of any solids in the boiler water.

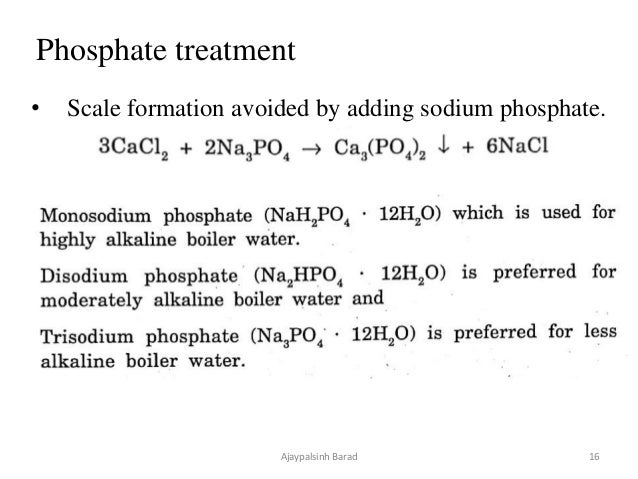

Boiler water carry over is the contamination of the steam with boiler water solids. If the ph gets to 11 the water will foam and prime like mad. Foaming of water in the boiler a is due to a high concentration of dissolved gases b can be controlled by adding sodium phosphate c can be controlled by adding more neutralizing amines d can be controlled by adding sulphur to the feedwater. This can be written as.

Fire extinguisher type of fire extinguisher 1 water 2 co2 3 dry powder 4 foam extinguisher 1 water extinguisher advantage cheap best extinguishing agent for solids disadvantage rarely allowed by the fire brigade as the primary extinguishing agent for professional use foam and powder are allowed not frost resistant limited use only class a not suitable for use near electrical. It is generally believed however that specific substances such as alkalis oils fats greases certain types of. In this post we discuss the advantages and disadvantages of a combi boiler. The dead men used baking soda to lower the ph of the water and cure the foaming problem but there are also commercial chemicals available that can remove foam.

Steam heating boilers work best with a ph of between 7 and 9. Both mechanical factors such as boiler design high water levels load characteristics and chemical factors such as high solids concentration excessive alkalinity. Fast response built into a system boiler is a pump which makes the boiler respond quickly. Boiler a boiler is a device for generating steam which consists of two principal parts.

However because foaming is endemic to boiler water a better understanding of foam itself is required.