Electric Duct Heater Pressure Drop

Commercial industrial applications commercial industrial retail education residential.

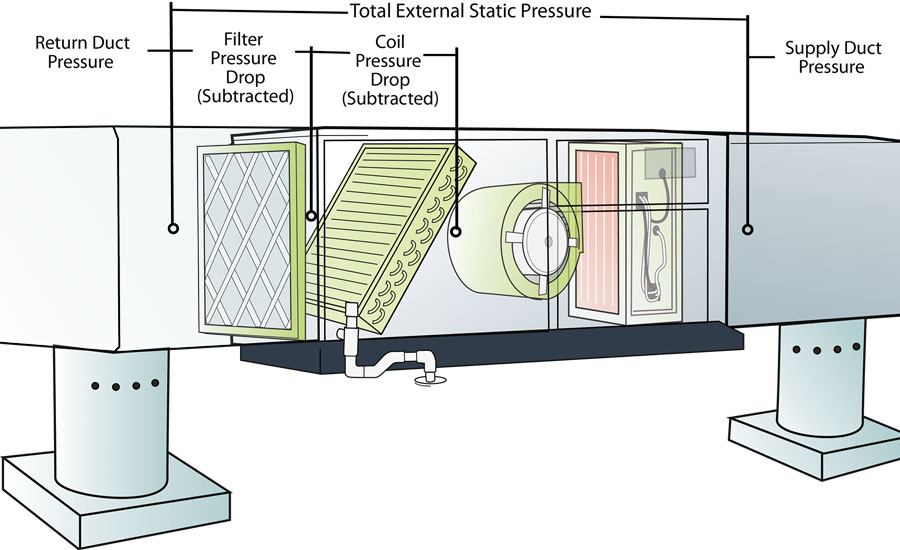

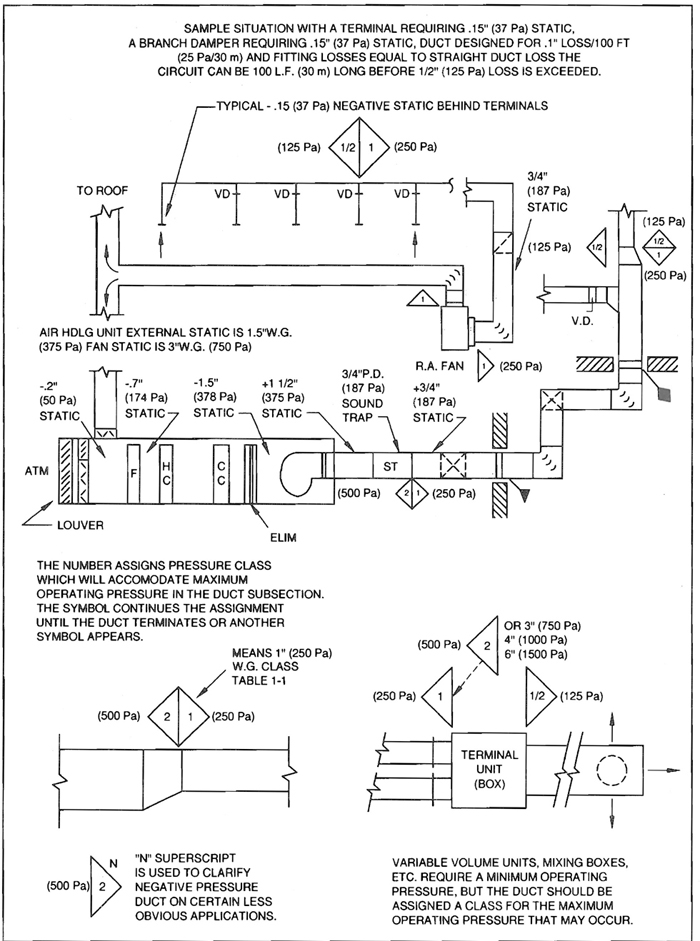

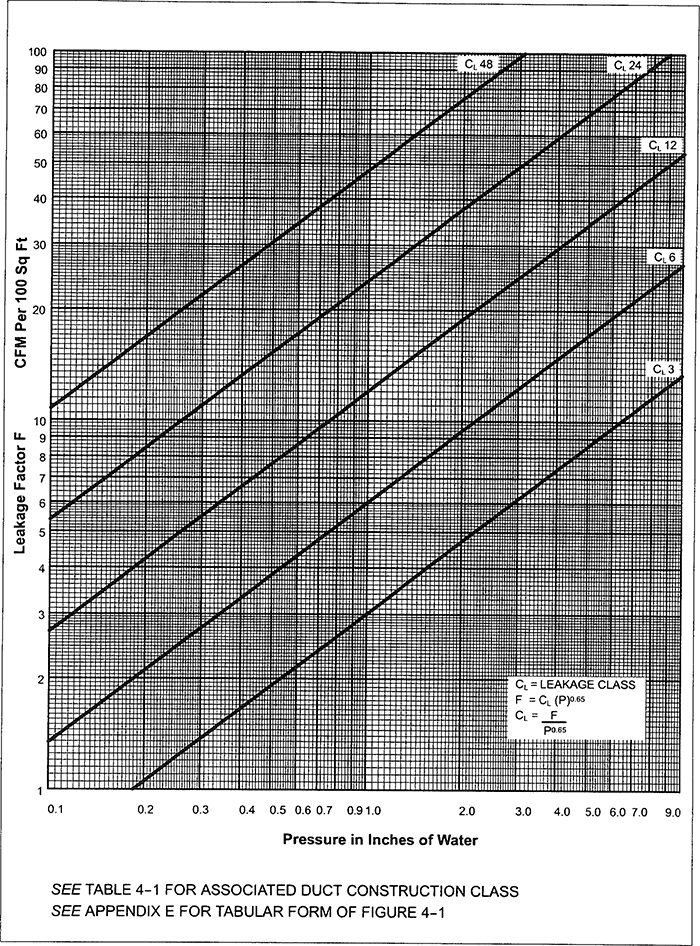

Electric duct heater pressure drop. Stab in electric heaters. Low pressure drop because of the high percentage of open space across the heater open coils have very low pressure drop as compared to finned tubular heaters. Calculating pressure drop through a heater the chart shown below is the approximate pressure drop through a heater based on the velocity of the. Their applications vary from a partial or auxiliary nature to being the major or principal heat source in a building.

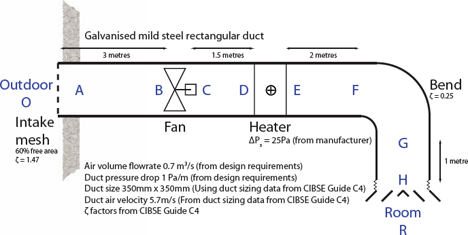

Duct size equal 2 ft. However if pressure plates must be added to an open coil the pressure drop over the open coil far exceeds the drop over a. Same concentration of wattage as an open coil heater. Open coil duct heaters have listing of 22 5 kw per square foot.

For tubular duct heaters the limitation is usually about 13kw per square foot. Wattage calculation formulas and table. Sheath temperature and air velocity graph. Fresh air heater today s airtight homes and offices beg for fresh air.

20 000 3333 6 c. X 3 ft total watts equal 20 000 watts per sq. Maximum discharge air. Inches h20 kw ft 2 x velocity in fpm 2 760 500 8.

Since an electric duct heater has a constant btu h output as long as the heater is energized a mini mum air velocity must be maintained through the heater. To properly match a duct heater to an application the wattage air velocity and element watt density must be determined. Electric heater thyrister control panels. This can result in reduced fan 2 motor horsepower and makes it possible to retrofit open coil heaters into existing systems without changing the fan motor.

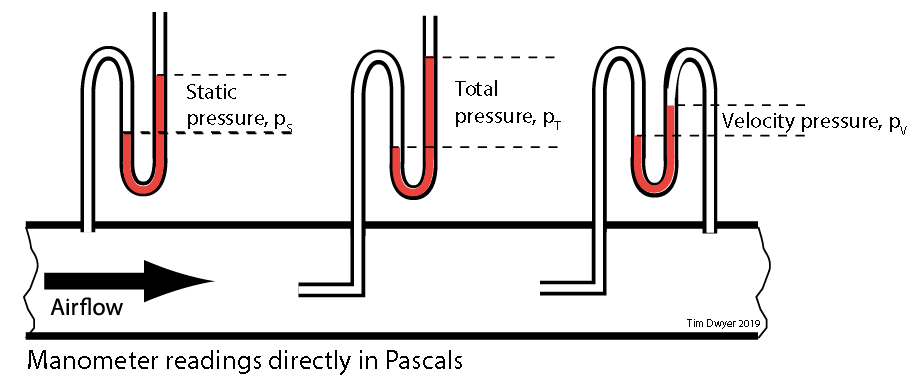

Electric heater duct cassette sections. Element watt density vs. The pressure drop across a finned tubular heater is greater than across an open coil. Static pressure drop through an open coil heater is quite low and in most cases can be ignored when calculating system pressure drop.

Thermolec electric duct heaters are designed for use in all forced air commercial and industrial hvac systems. Formulas and graphs that will aid in your design include. If airflow in the duct is expressed in fpm then a direct cross reference can be made by comparing the temperature of the air as it enters the duct heater to the kw rating on the table at the rated air velocity. This can result in reduced fan motor horsepower and makes it possible to retrofit open coil heaters into existing systems without changing the fan motor.

.png)