Electric Motor Windings Fail In Which Of The Following Conditions

As an example if a motor that would normally.

Electric motor windings fail in which of the following conditions. Open type electrical motors will fail in wotf three areas. Choose the right motor for the conditions in which it will be run. Stressful mechanical environmental and electrical operating conditions can all cause electric motor failure. Electric motors should be installed very carefully and should be looked after at regular intervals.

1 motor overloads. Electrical failures are winding failures caused by an open contactor bad connection blown fuse excessive heat electrical overload or broken power lines. How can a bearing failure be determined in a hermetic compressor motor. When you suspect an issue with your electric motor winding there are three categories of measurements to help identify the likely source of failures electrical mechanical and thermal.

With a multimeter set to low ohms usually 200 test between each winding terminal and the metal casing of the motor. The megger will help to detect areas of deteriorating insulation where the windings may soon short. When a bad motor winding cannot be found by a physical inspection many times an ohmmeter may show that there is a defective winding. To get a complete picture evaluate the likely failure modes and match the right maintenance technologies with the most likely failure mode.

Do the following with the motor disconnected. Maintenance experts agree that excessive heat causes rapid deterioration of motor winding insulation. Most of them are caused by the over heating of motor. Amperage readings noise and seized.

There are also other factors which greatly affect the performance of electric motors such as low resistance dirt moisture over current and vibrations. Most repair shops will use a megger or a ground insulation tester. Most of the electric motor failures occur at the start up. Electric motor windings fail in which of the following conditions.

Even the best motors will fail prematurely if they re installed in applications or conditions they re not rated for or if preventative maintenance guidelines are not followed. Windings bearings and centrifugel switch. To check an electric motor to see why it failed look at. What is the major cause of contact misalignment.

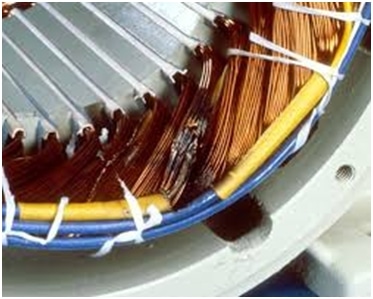

Winding failures are some of the most common electric motor repair causes. Open type electric motors will fall is which of the following three areas. All of the above. Sounds like you have a winding down to ground.

On line technologies permit assessment of the entire motor system to facilitate troubleshooting. The common rule states that insulation life is cut in half for every 10 c of additional heat to the windings. Windings centrifugal switch and bearings. All of the above opens shorts and grounds.

The winding failures illustrated here are typical of what can happen is such circumstances.