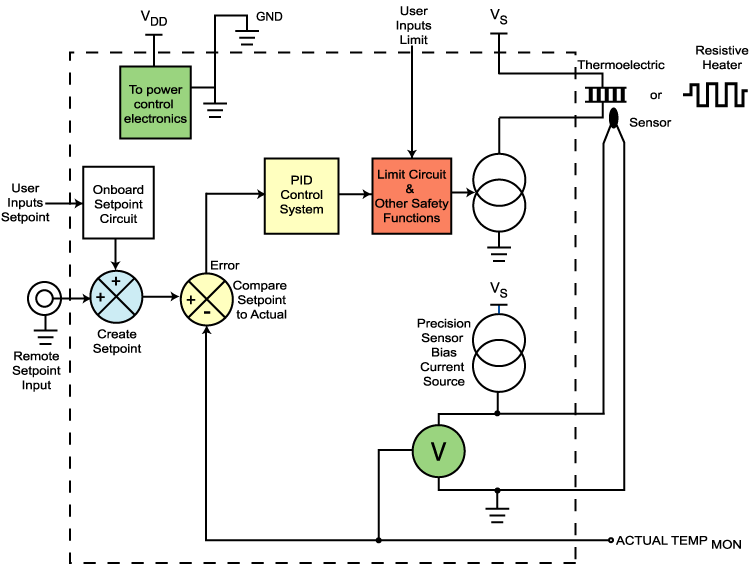

Electric Toaster Control System Block Diagram

Introduction electromechanical systems are hybrids of electrical and mechanical variables.

Electric toaster control system block diagram. An old but interesting booklet that covers how toasters convert electrical energy into heat. The structure of an electromechanical drive system is given in figure 2 1. It is the time taken by the control system to achieve its stable output. An automatic toaster with feedback is taken as an example of the practical closed loop control system.

A good control system possesses high speed. Also explains the thermostatic control system that switches a toaster off. The block diagram is to represent a control system in diagram form. A basic 48 page introduction to toasters how they work and who invented them.

The input of the system is desired quality. Toasters by elaine marie alphin. Then the task of clothes drying is an user issue. Types of control systems.

Applications for electromechanical components range from robot control sun and star trackers disk drive position control dc machines control and central air conditioning systems for residences. It is not always convenient to derive the entire transfer function of a complex control system in a single function. The block diagram is shown in figure. A small numbers of oscillation or constant oscillation of output tend to indicate the system to be stable.

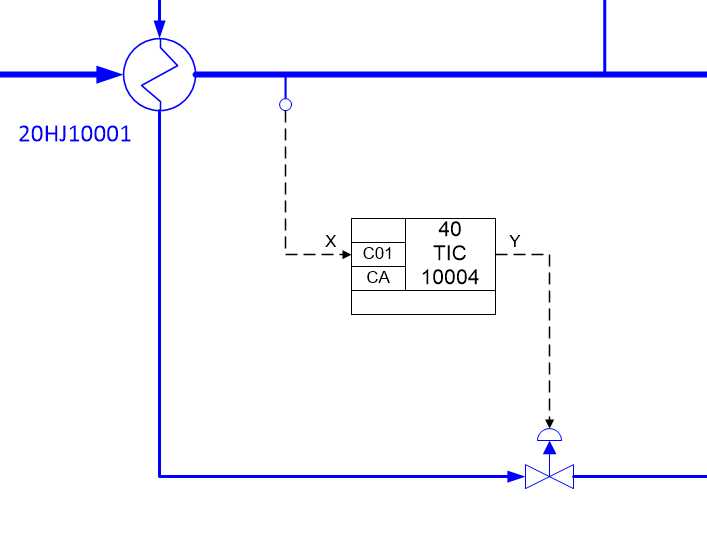

The transient period for such system is very small. It is easier and better to derive the transfer function of the control element connected to the system separately. The user can adjust the drying process of the system by setting the timer controls as per his requirement. B practical closed loop system.

The system input is also ineffective to disturbance produced in the toaster due to loss of addition of heat from surroundings. Observe the below block diagram for the open loop control system electric drier.