Esd Floor Testing Equipment

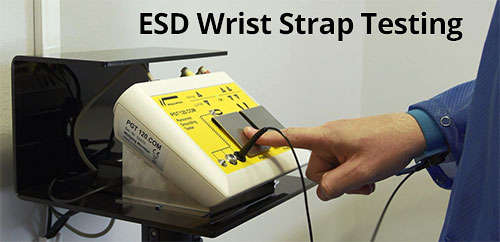

They are considered the most favored method for monitoring esd floors.

Esd floor testing equipment. Esd test equipment is used to verify the performance of items used in an esd area or test for the susceptibility of damage from an electrostatic event to a device or component. Do you have a copy of this test method. A southern california company installed esd flooring in their research labs. The third party measured electrical resistance per esda standard test method ansi esd stm 7 1.

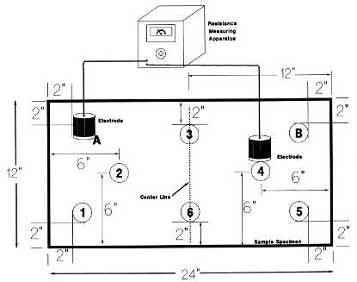

Measures voltage generated on the body while walking body voltage is displayed on meter as well as live via a computer the body voltage is graphed in real time on an easy understand interface. Hopefully your goal is to identify flooring options that meet standards like ansi esd s20 20 2014. However requires special knowledge and elaborate testing equipment so it s typically only used during the qualification phase. When it comes to esd flooring the test method you need to follow is ansi esd stm 7 1 2013.

To evaluate the potential for charge generation we use ansi esd test method 97 2 2014. To meet standards you need to utilize standard test methods. The only way to predict whether a floor will sufficiently inhibit static is by testing the flooring system that is testing the floor in conjunction with the subject wearing all types shoes to be worn in the environment. Daily testing ensures proper function and resistance levels.

Surface resistance tests can be performed easily and verified with inexpensive and readily available equipment. Some sections of the floor wear more quickly based on foot traffic volume or equipment use. As part of the lab commissioning protocols they hired a third party to test the static control properties of their new floor. Esd floor products.

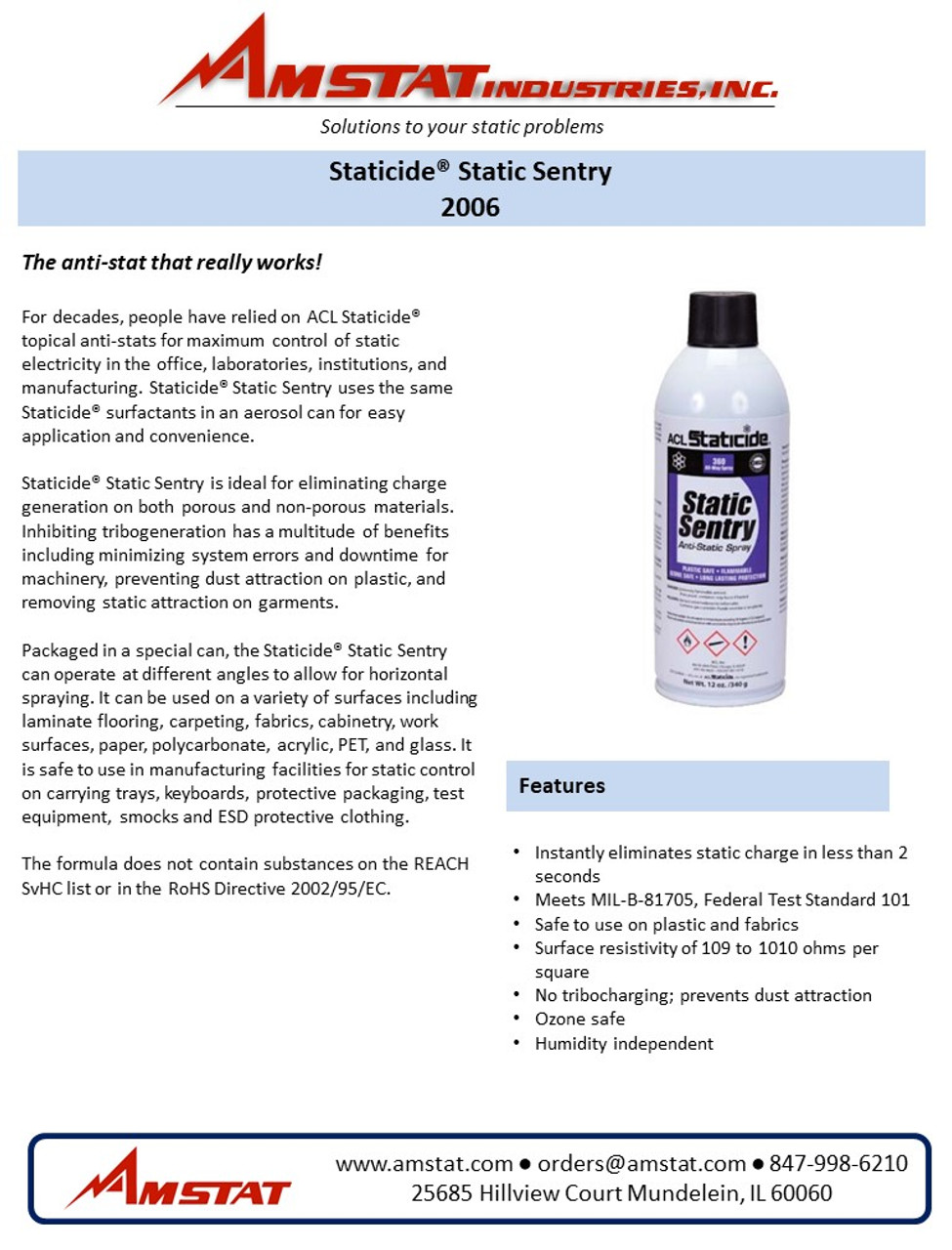

The new static solutions ohm stat esd fm 1126 field meter is a palm sized electrostatic measuring device ideal for testing static voltages polarities and even the ion balance of esd ionizers. In an effort to help facilities protect their employees and equipment through flooring that meets electrical safety standards staticworx inc north america s largest manufacturer of static control flooring products and services has launched a groundsafe initiative. The surface of the floor provides a path of moderate electrical conductivity between all persons and equipment making contact with the floor to prevent the accumulation of dangerous electrostatic charges. Testing your esd floor making sense of esd standards.

The fm 1126 is robust lightweight and compact making it ideal for the periodic verification of the static control processes used in your facility. Self install esd flooring kits electronics and pcb facilities require esd flooring to prevent erroneous charges from damaging sensitive equipment.