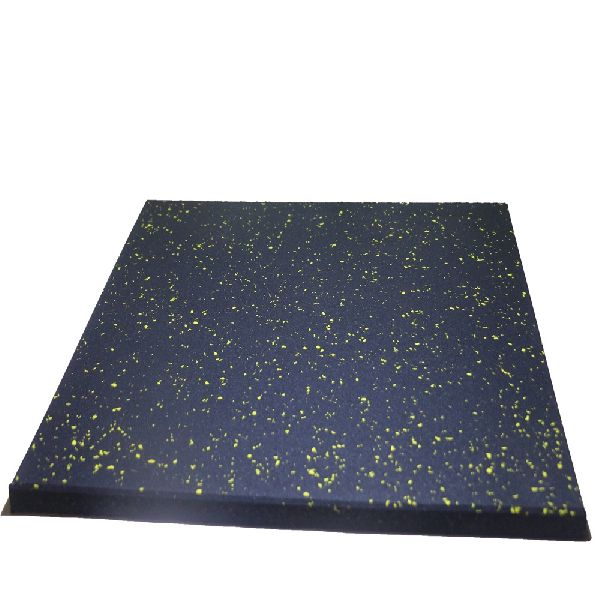

Epdm Rubber Coefficient Of Friction

Static friction results from the normal force of two objects in contact acting opposite the intended motion of one surface against the other.

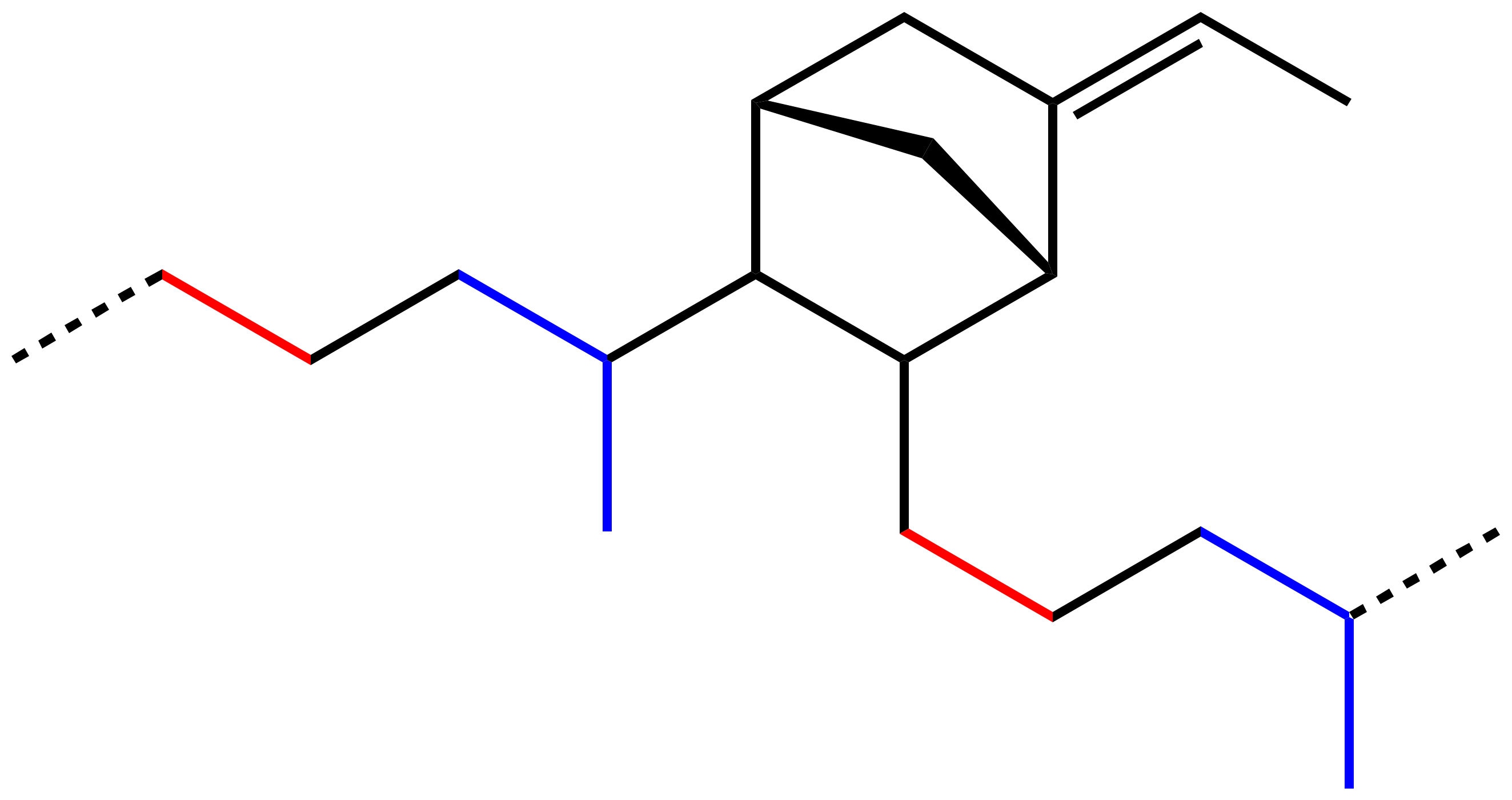

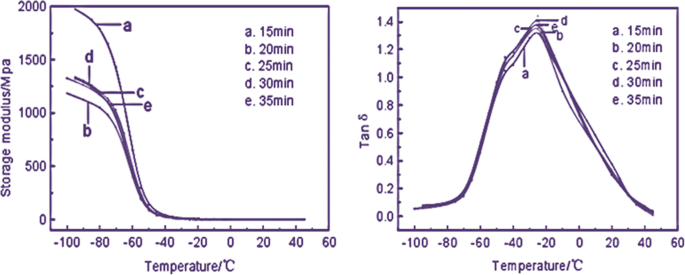

Epdm rubber coefficient of friction. N normal force between the surfaces n lb there are at least two types of friction forces. The results of the tests and the simulations were compared with each other and discussed. In the present work friction and sliding wear behaviors of indigenously developed ethylene propylene diene monomer rubber epdm of different hardness have been studied against steel counterpart in dry condition. Rubber epdm was measured in an oscillating rolling ball steel on plate rubber configuration oscillating rbop and simulated by fem.

μ static μ s or kinetic μ k frictional coefficient. The coefficient of frictions cof and specific wear rates of the epdms were determined. Further aim of this work was to investigate on how the friction and wear properties of the epdm rubbers depend on the configuration of the testing rigs. Studies in the literature suggest that the cof between a dry epdm.

For example static friction can prevent an object from sliding down a sloped surface. Fric tion force normal load and coefficient of friction cof were determined. The maximum force of static friction can be calculated by multiplying the normal force by the coefficient of friction specific to the pair of materials in contact. The coefficient of static friction typically denoted as μ s is usually higher than the coefficient of kinetic friction.

Dry rubber dry steel 0 80 0 76 0 95 dry rubber greasy steel 0 80 0 76 0 95. Static friction is friction between two or more solid objects that are not moving relative to each other. F f frictional force n lb. The friction coefficient cof of the epdm seal and plate was not experimentally measured and is therefore unknown in this study.

A similar tendency was found for the cof in rop tests. Hardness shore a polymer compound type coefficient of friction. The friction values used in the material interaction table are generalized values based on the following references. It was found that with increasing cb content the specific wear rate was reduced.

Dry steel dry steel 0 70 0 57 0 80. The frictional force can be expressed as. Bowden tabor the friction and lubrication of solids oxford. The friction force is the force exerted by a surface when an object moves across it or makes an effort to move across it.

The resistance to polar substances and steam are also good. The rubber stocks were prepared in a laboratory internal mixer and the curatives were introduced on a laboratory open mill.