Epdm Rubber Extrusion Process

Metal conveyor epdm tpv flock silicone coating assembly facilitating coating and mounting strap can be used on the same line allowing standard profil who uses a wide range of compounds with varying levels of rigidity and density to deliver.

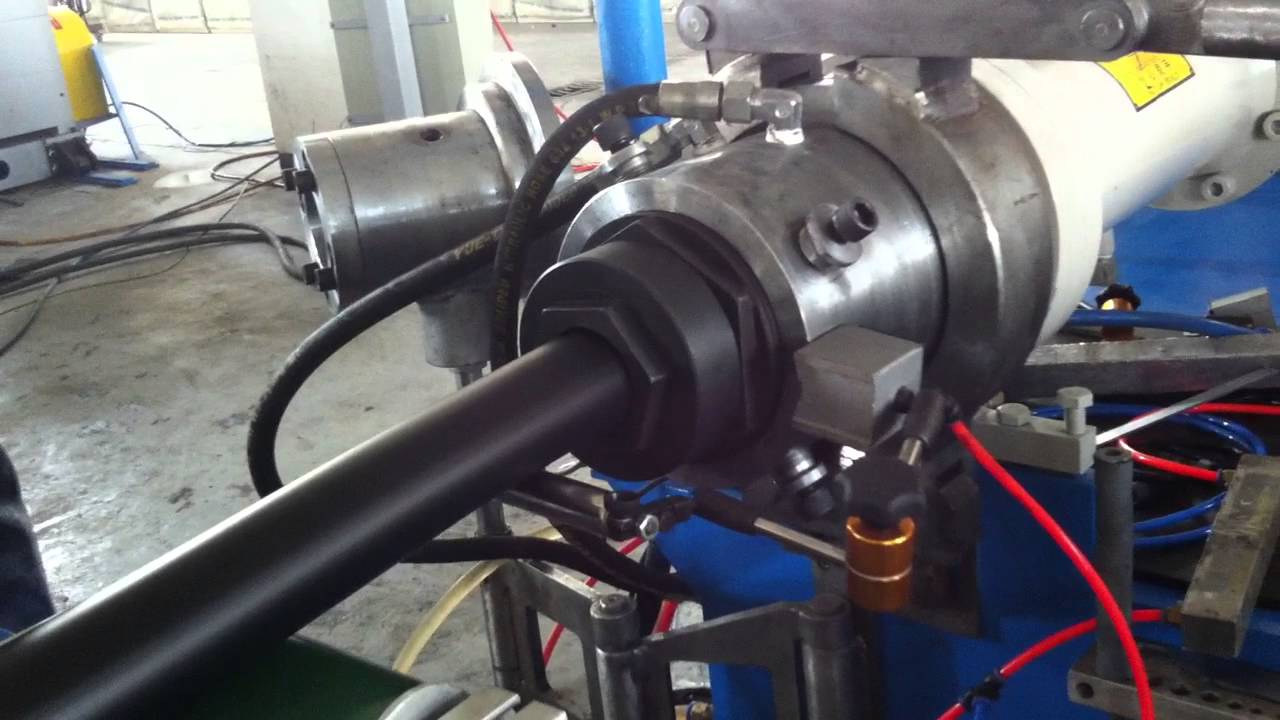

Epdm rubber extrusion process. Standard profil has nearly 40 years of experience in epdm extrusion. The extruder consists of a rotating screw inside a close fitting heated barrel. Initially the die plate is warmed with an external heat source to aid polymer flow in the early. The profile die is implanted at the head of the machine by means of a winded and secured wheel.

The profile die is located the head of the machine by means of a threaded locking ring. Epdm rubber ethylene propylene diene monomer rubber is a type of synthetic rubber that is used in many applications. As rubber is not a good conductor of heat to ensure this method works efficiently the rubber material must be. In addition to epdm these extrusion lines use tpv as another coex.

Rd modern industrial area xianju. The purpose of the extruder is to soften and pressurize the rubber as. In the extrusion process the rubber compound which includes the polymer epdm fillers and additives such as pigments curing agents antioxidants and processing aids is fed into an extruder. The rubber extrusion process begins with a rubber compound being fed into an extruder.

For extrusions manufactured from rubber compounds the process of extrusion is basically the same in that you have an extrusion machine or extruder. Salis zhou zhejiang baina rubber plastic equipment co ltd add. Any more question please contat me. Build a knowledge base that encompasses products ranging from intricate profile extrusions to tires using compositions ranging from a single thermoplastic elastomer to multiple dense and cellular compounds coextruded with carriers and reinforcements.

Epdm is an m class rubber under astm standard d 1418. Extrusions can be manufactured in various materials from rubber thermoplastic elastomer or thermoplastics. Epdm is made from ethylene propylene and a diene comonomer that enables. The procedure of extrusion essentially requires an extrusion machine or extruder.

Once the product has come into the desired shape the cooling and the wind up process is carried out which is similar to the process followed in the salt batch continuous cure rubber extrusion process.